More and more businesses are issuing laptops as mobile workstations to equip an increasingly mobile workforce. In some cases, tablets are filling the role that clipboards of documents used to, with the advantages of internet connectivity and a built-in camera. Mobility has a lot of advantages, but it also subjects devices to a lot more wear and tear than the standard office desktops ever faced.

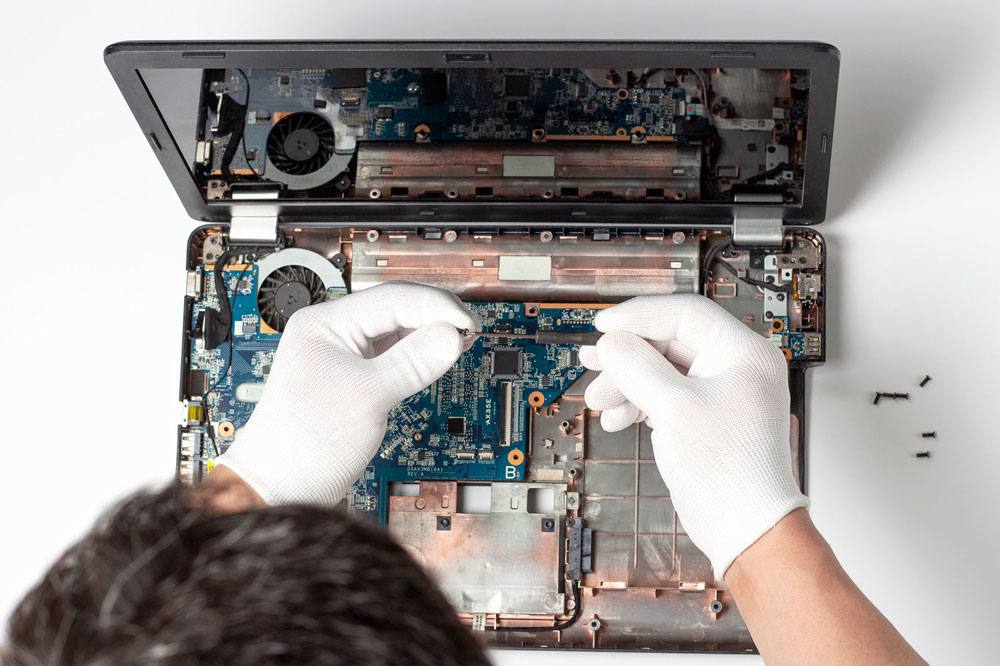

When you take a laptop, tablet, or other electronic device apart and see just how tightly packed everything is in there, it’s not surprising that these devices can be so fragile and susceptible to bumps, drops, impacts, and cracks. They’re designed for efficient use of space, and that doesn’t include much padding or buffer. That’s only become more true as manufacturers have pushed toward thinner, lightweight electronic equipment.

The average turnover rate for consumer electronics is three years, as a result of both wear and tear, and needing more computing power to keep up with the latest generations of software.

But it’s a mistake to think of this equipment as “e-waste.”

The ultimate goal of electronic recycling is to reduce hazardous waste, and one of the best ways to do that is to keep usable materials – and equipment – in circulation for as long as possible before they are replaced. That’s why e-recyclers like Cobalt are emphasizing proper disposal and reuse of electronics.

Often there’s only one major thing wrong with a piece of equipment that renders it unusable. Even if one critical component is damaged, it’s very likely that a unit still has value due to the heavy metals present. It could be repaired and refurbished instead of taking up space in a landfill.

If you want to protect the value of your equipment, treat it right. Units that might otherwise have had resale value can be downgraded or disqualified because of a banged-up case, a cracked screen, missing keys on the keyboard, or a busted hinge on a laptop screen. Consider issuing padded cases or bags to employees using laptops or tablets to prevent excess wear and tear that could diminish the equipment’s value.

When You Recycle, Make Sure the Recycling Center is Certified

You want to make sure to choose an electronics recycler that is certified by R2 or e-Stewards to guarantee that data-bearing devices like hard drives and laptop computers are handled securely and all data is destroyed. Some e-scrap recyclers simply collect electronics and sell them in bulk with no data security measures at all. Certification prohibits this behavior and even requires the electronics recycling company to hold its buyers to the same standards. (Learn more about Cobalt’s R2 Certification)

Bulk sales e-scrappers and brokers can operate this way because they save on the costs of testing, sanitizing, refurbishing, and shredding that are necessary to dispose of electronics responsibly. So while they may be selling a lower-quality, higher-risk product, they can still maintain their bottom lines. Certifications themselves also require significant investment and are backed up by regular audits. Be sure to ask for documentation on the recycler’s certification.

If you’re a business looking to dispose of your retired equipment in bulk, make sure your vendor offers a certified, full-service electronics recycling program.

How to Choose an Electronics Recycler for your old electronics:

Selecting an electronics recycler for your business is an important decision with implications for your exposure to liability. Every organization has unique needs, and decision-makers need to be asking the right questions to ensure that those needs are met.

To help you evaluate recyclers, we’ve assembled this easy guide to the top concerns that will reveal any potential gaps or drawbacks to their program.

Electronics Recycling Certifications

Choosing a recycler that has been certified specifically for electronics is the first step in protecting yourself against what could go wrong. There are a number of environmental, quality, safety, and security measures built into these certifications to hold recyclers accountable for how they handle their clients’ assets. Ask your recycler which certifications they hold, how often they are audited, and what they are doing to stay current with industry standards.

Chain of Custody Reporting

When your equipment potentially has personal employee or customer information, sensitive financial data, and/or intellectual property on it, it’s imperative that your recycler be able to detail exactly where every asset is in the process and support that claim with the proper documentation. Ask your recycler if they are protecting you from these risks with full Chain of Custody reporting, including make, model, serial number, and/or asset tags. This reporting supports the transfer of liability of those assets and their data from your company to your recycler.

Data Destruction Practices

There is more than one way to properly prepare electronics for resale or recycling. You want to know what method or methods your recycler makes available, and how they guarantee that your data security is protected. You also want to know just where your electronics are destined to end up: will they be refurbished and resold, or destroyed for scrap? Both ways are legitimate, but the last thing you want is a surprise.

Cobalt will provide data destruction for all fixed storage devices. Read our Data Security Policy

Quality of Service

Managing end-of-life electronics is painless when you work with a partner that values convenient, comprehensive service. A broad range of services allows for customizable solutions and peace of mind that all the details are being covered to maintain compliance, without demanding extra oversight or homework from you.

Cobalt makes it easy for businesses to recycle their electronics. Our menu of services includes many measures for ensuring that your assets are handled in a safe, secure manner from collection to final disposition.

Proper Equipment Collection

We’re ready to do everything it takes to get your material to our state-of-the-art processing facility, even preparing and packaging it for you. This is our White Glove service.

Secure Transportation

Your hardware is in safe hands with our qualified and background-checked employees, and protected from damage while in transit.

Assessment and Triage

Equipment that our experts deem reusable will undergo auditing and data sanitization. Hardware that fails our tests and end-of-life units are sent through a shredding system to be recycled.

Liability Insurance

Insurance works together with certifications and auditing to reinforce 360-degree protection. An uninsured or inadequately insured recycler could leave your organization and brand exposed without you ever knowing, unless you ask.

Physical Security

Any qualified electronics recycler will emphasize data security in cyberspace, but what about the real world risks once your assets have left your custody? This is an important detail that is often overlooked.

The Sum of IT’s Parts

Businesses upgrade their equipment every three to five years, roughly, and often do so all at once. (Otherwise, they might end up with the fabled closet of computers that no one goes into or talks about, but everyone knows is there.)

There are multiple steps in recycling electronics that come between the moment you turn over custody to a certified ITAD and e-waste recycler and when they can be used to manufacture new products.

Laptops are among the more labor-intensive devices to test, sanitize, and refurbish – a process that happens by hand, down to the last tiny screw.

Cathode Ray Tube (CRT) monitors contain hazardous materials and must be processed by a specialist in order to safely recover the recyclable metals (such as extracting lead from leaded glass).

Preventing Electronic Waste

Beyond that, e-waste is beginning to overwhelm the world. In 2019, nearly 54 million tons of e-waste was disposed of worldwide. That’s expected to grow by 2 million tons every year between now and 2030. Meanwhile, only 17.4 percent of globally generated e-waste was collected or recycled in 2019. That figure represents only a 0.4 percent increase from 2014-2019.

In other words, the world’s e-waste generation is growing much faster than e-waste is being collected or recycled.

To change that trend, we all need to do our part. Cobalt believes doing right by our fellow human beings and environment is a solid gold reason to properly dispose of obsolete electronics with a certified company.

To learn more about our services and speak to a professional about you can properly recycle your business electronics, call 513-433-2530 or contact us today.