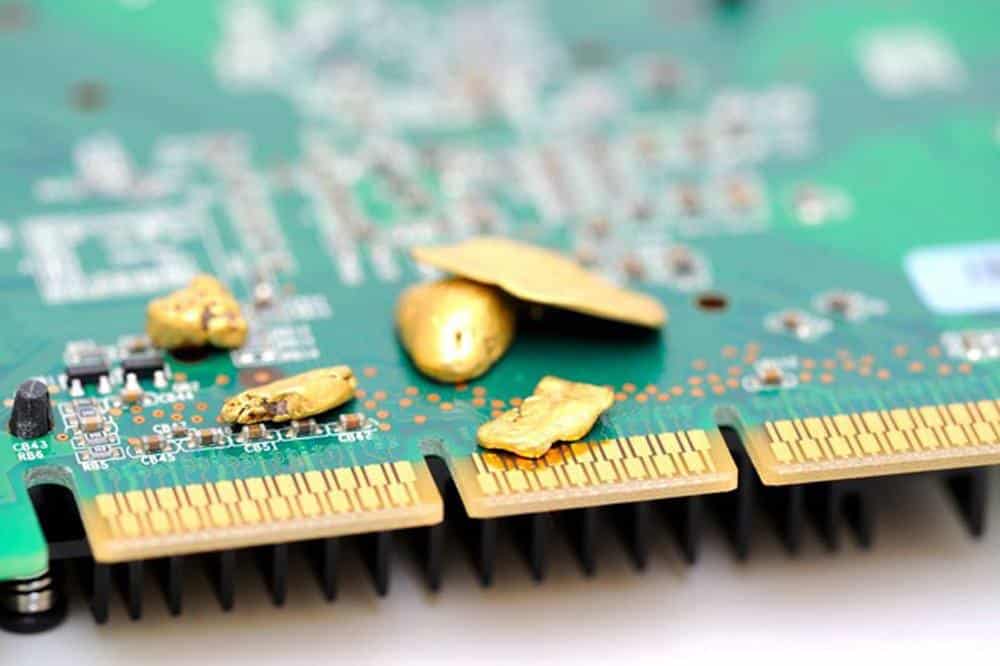

You have outdated or out-of-service IT equipment that’s ready to be disposed of, and you’ve also heard there’s gold, silver and other precious metals in electronics. So does that mean you’re sitting on a “goldmine” of potential revenue?

Not necessarily. While it’s true that there are precious metals in electronics, the economic value has not proved to be what many might have expected when e-waste recycling was still fairly new.

It turns out that it’s difficult to make recycling pay for itself, for reasons we’ll get into in a moment. But it’s still possible to recover at least some of the value of your original investment in IT equipment — it just won’t be from the gold.

The Motherlode of E-Waste Myths

It’s true there’s often silver, platinum, palladium and gold in our damaged or outmoded electronics, not to mention plastic, glass and other materials that have some scrap value. The primary reason is that precious metals conduct electricity much better than alloys. They also have properties like corrosion resistance and hardness that are important in electronic devices.

Volume is the key. The amount of any given metal in a single device is scarce. It takes a large volume of devices, or of component parts like RAM, to accumulate enough gold, silver, palladium or other rare metals to see a decent payoff from it. Individuals and companies that gather the amount of e-waste needed to make it pay are sometimes called “urban miners,” and they do it full time.

As great as a gold rush would be, the other thing limiting the value of IT equipment is the processing costs, which are often higher than what the precious metal ultimately will end up being worth.

So What is Old IT Hardware Worth?

There are three ways that a retired device can find value in a new life: resale of the whole device, resale of its parts, or resale of the material once it has been shredded. The path that any given device takes depends on its condition, how modern its components are, storage and RAM capacity, and other factors.

If a device is truly end-of-life, it will be destroyed in bulk with similar devices, and the separated recyclable materials will be sold as scrap for manufacturing. That would include any precious metals in the device – but those will make up only a miniscule fraction of the original weight.

Scrap commodities are traded by weight, and an 8-lb laptop or 25-lb monitor may only contain a few grams of precious metals at most. The majority of a device’s weight comes from less valuable material like plastic and glass.

A scrapped, shredded laptop might end up being worth about $10 per pound of material, maybe more if it is an older device and contains more gold. Newer-generation devices typically contain less gold as advancements in technology and efforts to reduce production costs have pushed tech manufacturers to design thinner, lighter, less resource-intensive units.

The Sum of IT’s Parts

If the device or its parts are instead being resold for secondary use, the value of the metal is irrelevant – all of those parts have their own market values. For instance, as of this writing, laptop RAM is worth about $20/lb – but, a single laptop may only contain 1 oz of RAM, so the value doesn’t start adding up until you’re dealing in bulk.

This is why businesses have an advantage over individuals when it comes to recovering value from e-waste. Businesses upgrade their equipment every three to five years, roughly, and often do so all at once. (Otherwise, they might end up with the fabled closet of computers that no one goes into or talks about, but everyone knows is there.)

There are multiple steps in recycling, refurbishing or reselling electronics that come between the moment you turn over custody to a certified ITAD and e-waste recycler and when they can be used to manufacture new products.

A full laptop, in good condition, and with modern components (e.g., Intel i3 or newer), may resell for about $40. But then you have to factor in labor, processing, storage and shipping, all of which eat into that value.

Laptops are among the more labor-intensive devices to test, sanitize, and refurbish – a process that happens by hand, down to the last tiny screw. CRT monitors contain hazardous materials and must be processed by a specialist in order to safely recover the recyclable metals (such as extracting lead from leaded glass). Likewise, devices that rely on batteries will lose value because those batteries must be recycled separately and safely.

Bottom Line: Doing the Right Thing with Old Electronics is Worth It.

Disposing of e-waste properly and safely is still important.

First, it costs less and is significantly less damaging to the environment to recycle precious metals than it is to mine them. One ton of circuit boards is estimated to contain 40 to 800 times more gold than one metric ton of ore.

Second, the heavy metals, batteries and other materials in electronic devices are often toxic and can contaminate groundwater near landfills if they’re disposed of in regular waste. That in turn becomes a human health risk to the surrounding community.

Beyond that, e-waste is beginning to overwhelm the world. In 2019, nearly 54 million tons of e-waste was disposed of worldwide. That’s expected to grow by 2 million tons every year between now and 2030. Meanwhile, only 17.4 percent of globally generated e-waste was collected or recycled in 2019. That figure represents only a 0.4 percent increase from 2014-2019.

In other words, the world’s e-waste generation is growing much faster than e-waste is being collected or recycled.

To change that trend, we all need to do our part.

Cobalt believes doing right by our fellow human beings and environment is a solid gold reason to properly dispose of e-waste with a certified company. We hope you agree. To learn more about our services and speak to an ITAD professional, contact us today.